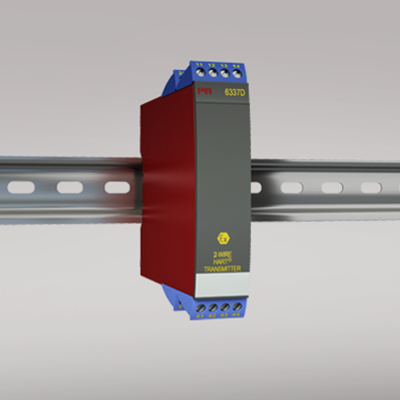

6337D

2-wire HART® transmitter

- 1- or 2-channel converter for RTD, TC, Ohm, and bipolar mV signals

- 2 analog inputs and 5 device variables with status available

- HART® protocol revision selectable from HART® 5 or HART® 7

- Hardware assessed for use in SIL applications

- Mounting on a DIN rail in hazardous gas and dust area

Manuals :

Data sheet :

Application

- Linearized temperature measurement with TC and RTD sensors e.g. Pt100 and Ni100.

- HART® communication and 4...20 mA analog PV output for individual, difference or average temperature measurement of up to two RTD or TC input sensors.

- Conversion of linear resistance to a standard analog current signal, e.g from valves or Ohmic level sensors.

- Amplification of bipolar mV signals to standard 4...20 mA current signals.

- Up to 63 transmitters (HART® 7) can be connected in a multidrop communication setup.

Technical characteristics

- HART® protocol revision can be changed by user configuration to either HART® 5 or HART® 7 protocol.

- The HART® 7 protocol offers:

∙ Long Tag numbers of up to 32 characters.

∙ Enhanced Burst Mode and Event notification with time stamping.

∙ Device variable and status mapping to any dynamic variable PV, SV, TV or QV.

∙ Process signal trend measurement with logs and summary data.

∙ Automatic event notification with time stamps.

∙ Command aggregation for higher communication efficiency. - 6337D is designed according to strict safety requirements and is therefore suitable for applications in SIL installations.

- Continuous check of vital stored data.

- Meeting the NAMUR NE 21 recommendations, the 6337D HART® transmitter ensures top measurement performance in harsh EMC environments. Additionally, the 6337D meets NAMUR NE43 and NE89 recommendations.

Mounting / installation

- DIN rail mounting with up to 84 channels per meter.

- Configuration via standard HART® communication interfaces or by PR 5909 Loop Link.

- PR 5106B or 9106B is recommended as a barrier for 6337D.

Environmental Conditions

Specifications range -40°C to +60°C Storage temperature -40°C to +85°C Calibration temperature 20...28°C Relative humidity < 95% RH (non-cond.) Protection degree IP20 Mechanical specifications

Dimensions (HxWxD) 109 x 23.5 x 104 mm Weight (1 / 2 channels) 150 / 200 g DIN rail type DIN EN 60715/35 mm Wire size 0.13...2.08 mm2AWG 26...14 stranded wire Screw terminal torque 0.5 Nm Common specifications

Supply voltage 8.0...30 VDC Voltage drop 8.0 VDC Isolation voltage, test / working 1.5 kVAC / 50 VAC Isolation voltage, ch. 1 / ch. 2 1500 VAC Communications interface Loop Link & HART® Signal / noise ratio > 60 dB Response time (programmable) 1...60 s EMC immunity influence < ±0.1% of span Extended EMC immunity: NAMUR NE 21, A criterion, burst < ±1% of span Input specifications

Max. offset 50% of selected max. value RTD input Pt50, Pt100, Pt200, Pt500, Pt1000, Ni50, Ni100, Ni120, Ni1000 Linear resistance Cable resistance per wire (max.), RTD 5 Ω (up to 50 Ω per wire is possible with reduced measurement accuracy) Sensor current, RTD Nom. 0.2 mA TC input: Thermocouple type B, E, J, K, L, N, R, S, T, U, W3, W5 Cold junction compensation (CJC) Constant, internal or external via a Pt100 or Ni100 sensor Voltage input: Measurement range -800...+800 mV Min. measurement range (span), voltage input 2.5 mV Input resistance, voltage input 10 MΩ Output specifications

Current output: Signal range 4…20 mA Min. signal range 16 mA Updating time 440 ms Load resistance, current output ≤ (Vsupply - 8) / 0.023 [Ω] Sensor error indication, current output Programmable 3.5…23 mA NAMUR NE 43 Upscale/Downscale 23 mA / 3.5 mA HART protocol revisions HART 5 and HART 7 Approvals

EMC EN 61326-1 ATEX 2004/108/EC KEMA 09ATEX0148 IECEx DEK 11.0084X FM 2D5A7 CSA 1125003 EAC TR-CU 020/2011 EN 61326-1 EAC Ex TR-CU 012/2011 Yes SIL Hardware assessed for use in SIL applications